In the 18th century, sailing the seas on a wooden ship was a dangerous proposition. Sailors would face daily dangers of sea and bad weather, cramped conditions, sickness, and even battle injuries. Among these many challenges in the life at sea, ships were sailors' temporary houses, and they were under the constant threat posed by the infamous shipworm (especially Teredo navalis), a group of mollusks that can wreak havoc on even the toughest timbers by honeycombing with their tiny, sharp shells, and putting ships and their crews at risk, often within a short time.

Damage caused by Teredo after 4 years of activity. Port of Norderneyer. Credit: Tone4751 – CC-BY-SA-4.0

But a solution emerged to revolutionize the maritime industry: brass and copper sheathing. In 1761, the Admiralty, the organization responsible for the command and control of the Royal Navy in the UK, made an important decision.

They would have the hull of a frigate – HMS Alarm – sheathed with copper.

His Majesty's Ship the Alarm, conducting a Spanish Prize into Gibraltar; etching – Public domain

The result was a resounding success, leading to most of the Fleet, including the flagship Victory, being given copper bottoms. This simple innovation offered protection against shipworms and barnacles, and improved the performance of ships, making them faster and more resistant. It was only natural for this practice to be adopted by other vessels that sailed in tropical waters.

However, copper wasn't without its drawbacks. This expensive metal became less accessible when demand grew and prices rose. It was prevalent only until 1832, when G.F. Muntz patented a brass alloy that contained 60% copper and 40% zinc. It was more affordable and almost as effective as copper. This new material, known as Muntz metal or "yellow metal," replaced copper for sheathing and was also widely used on wharves.

The restored stern of the Cutty Sark [built in the 19th century] (with stern draft and rudder) sheathed in Muntz metal [brass]. Credit: Cmglee – CC-BY-SA-3.0

As iron ships became more pervasive in the 19th century, Muntz metal sheets continued to be used in smaller vessels.

During World War II, Muntz metal was used to sheathe nearly all Admiralty motor fishing vessels and small craft operating in warm harbors and seas. It remained a reliable and effective material for maritime use even as technology advanced.

Naval brass is defined as a really similar alloy (59% copper, 40% zinc), with the addition of 1% tin.

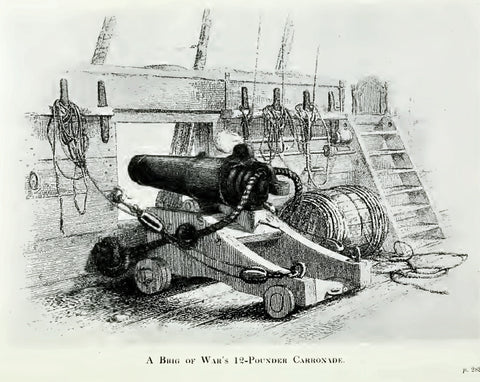

Copper and Muntz metal weren't just useful for sheathing the bottoms of wooden ships, though. During Nelson's day, the revival of the brass cannon was a noteworthy feature on warships. Large brass carronades were installed on some ships, and their devastating power was feared by many. According to contemporary accounts, they were even more frightening than conventional cast iron guns due to their superior range and accuracy.

Illustration of a "12 pounder" carronade on a 19th century brig of war. Source: Ships and Ways of other Days – Public domain

In conclusion, copper and brass have played a crucial role in the maritime industry, protecting ships from shipworms and improving their speed and resistance. From the Admiralty's decision to sheathe the frigate Alarm with copper to the invention of Muntz metal and its use during World War II, these powerful metals have had a lasting impact on seafaring.

If you're captivated by how brass participated in maritime innovation, don't forget to check out our catalog for a range of exciting products that pay homage to this era. Whether you're a collector, historian, or simply looking for unique and memorable gifts, we have something for everyone!